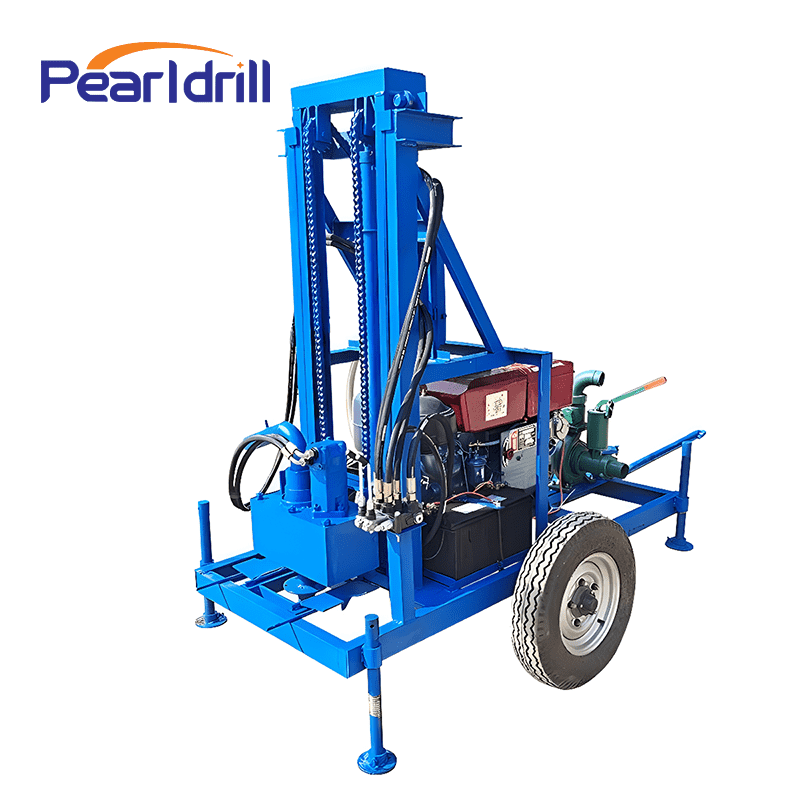

Portable water well drilling rigs are lightweight, easy-to-operate and mobile drilling equipment typically used for applications such as small-scale, water development and shallow well drilling.

Its advantages are as follows:

Easy to move: due to its small size and light weight, the portable water well drilling rig can be easily transported and moved between locations for small-scale operations, suitable for agricultural water well irrigation, backyard water well excavation, and other small-scale water well excavation.Easy to learn and use: the portable water well drilling rig is designed to be simple and easy to use, the operator usually does not need too much specialized skills to master the operation in a short time, which reduces the difficulty of operation.

Efficient drilling: Despite its small size, the performance of portable drilling rigs is usually sufficient to complete the drilling tasks of small depth boreholes, mainly focusing on the digging of water wells of less than 100m in the case of simple stratigraphy.

Lower equipment cost: portable water well drilling rigs are usually cheaper than large drilling rigs, with lower purchase and maintenance costs.

Easy to disassemble: portable water well drilling rigs are usually designed to be disassembled for easy transportation and storage, and can be transported by small vehicles, which is suitable for drilling operations in places with limited transportation.

Summarize:

Portable water well drilling rigs have the advantages of high flexibility, easy operation, easy transportation, cost saving, etc. They are especially suitable for small drilling operations, shallow water well drilling work.

If you need to buy water well drilling rig, click the link below to contact our professional team directly.

Comments

Post a Comment