If you have chosen your drilling site wisely and the borehole is still intact at the end of the drilling, it is time to test the water output of your well.

After measuring the initial water level, use a scoop to pump out as much water as you can in 10 minutes, then pour it into a bucket for further measurement. Once you have finished scooping, check the water level again.

If you can pump about 2.6 gallons (10 liters) of water per minute with little or no drop in the water level, your well is probably pumping enough water to supply the hand pump. However, don't be alarmed if the well goes dry in as little as 10 minutes. It is normal for an undeveloped well to produce very little water. Repeat this process for two to four days. If the well is still dry at this point after a short scoop, the water flow may not be sufficient to support the well.

At this point, you should perform a water quality field test. There are a variety of kits available; use the one you are most familiar with because accurate results are important.

Based on the test results, you will need to make a decision. Should you develop the well and install a pump, or start over at a new location? Poor water quality can affect the health and safety of humans, plants and animals that depend on the well, so use the parameters listed in the test kit to decide whether to proceed with development. Additionally, if the well is producing less than 2-4 gallons per minute, there is no guarantee of water production with a hand pump. If this is the case, repeat the drilling process and subsequent steps.

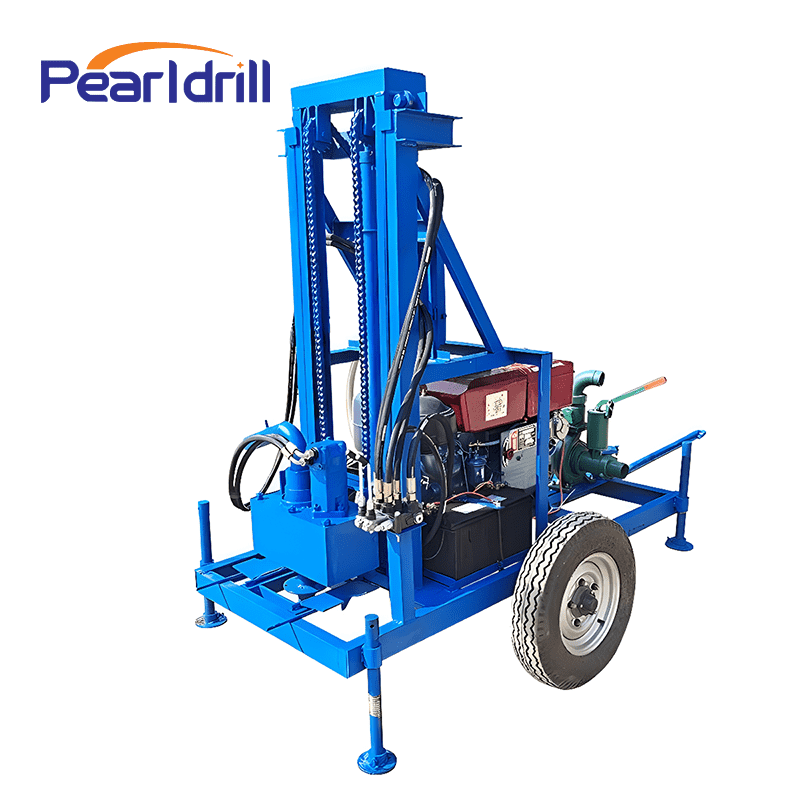

If you need a water well drilling rig, click the link below to contact our professional team directly.

Comments

Post a Comment